For the Operation of Milling Machine Which Motor Is Used

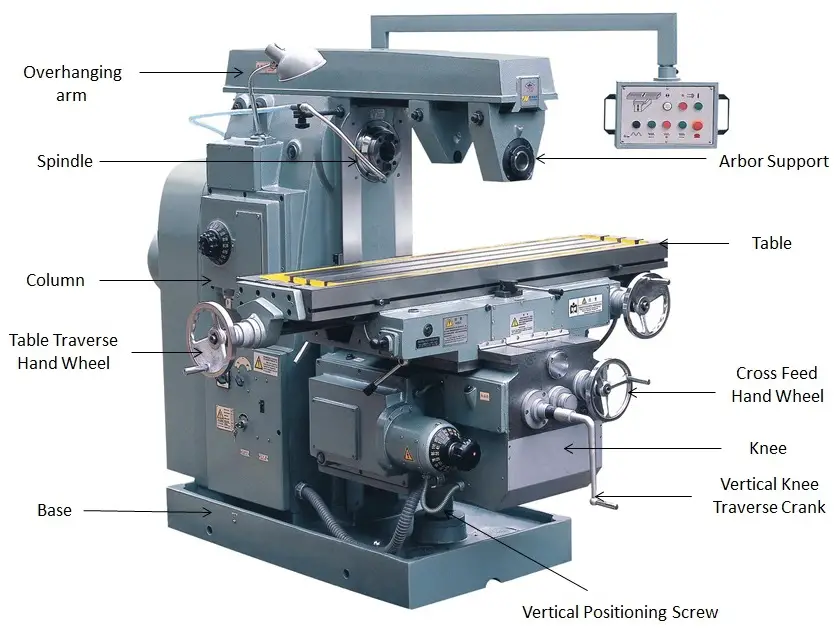

Hence it is used for heavy duty applications such as electric railways mine hoists. The plain horizontal milling machines column contains the drive motor and gearing and a fixed position horizontal milling machine spindle.

Msc Industrial Supply Co Tech Essential Mill Machines

The C-Frame milling machine is very robust and runs on a hydraulic motor.

. There are various milling machine operations used for different kinds of jobs. Once an axis is located at a desired position and will no longer be fed it should be locked into position with the gibb locks. MILLING MACHINE OPERATIONS - OD1644 - LESSON 1TASK 1 2.

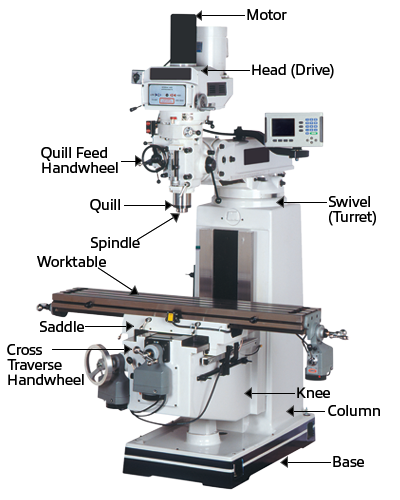

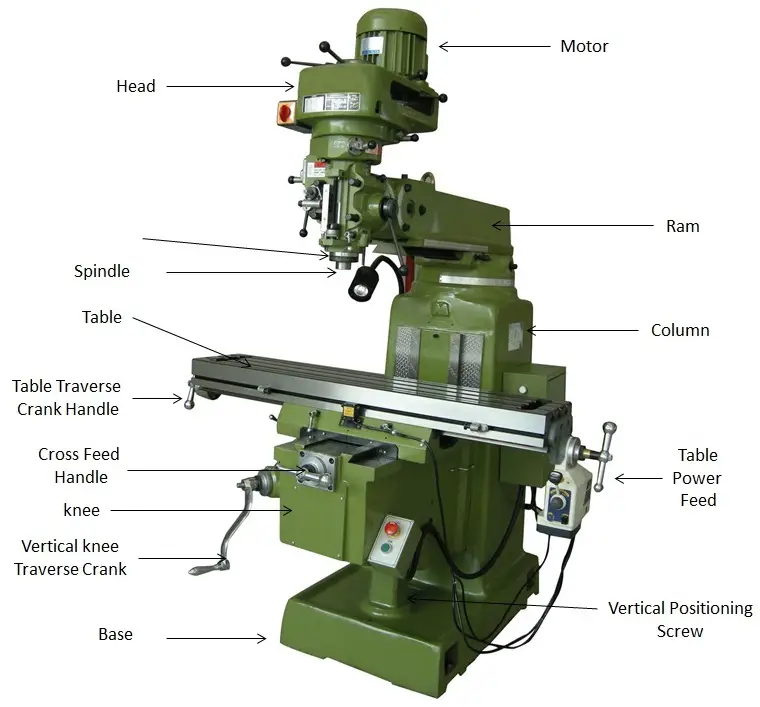

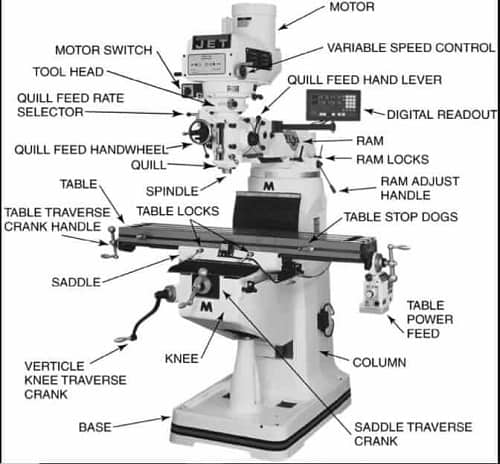

The spindle can be fed up and down with a quill feed lever on the head. CNC is the most versatile milling machine which is control by a computer. The milling machine is believed to come into existence in 17 the century.

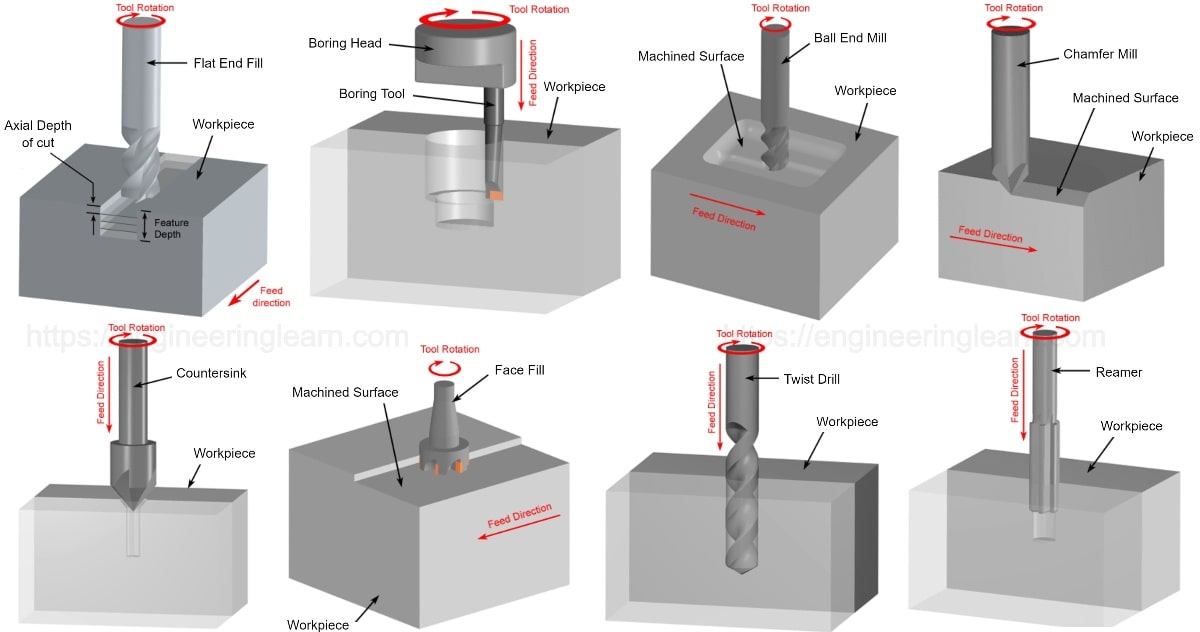

In this operation cutting forces act upward direction. The various operation performed by milling machine are described below. Just a s other the cutters are mounted on the arbor.

Therefore DC shunt motor or squirrel cage induction motors are suitable for the operation of milling machines. Then in the 18th century in the united states a machine was used which was similar to the lathe machine but in this machine The cutting tool is used to rotate and the workpiece uses to remain stationary. The wear-resistant castings are made of vanadium-titanium wear-resistant cast iron and the important parts are made of high-quality alloy steel which is stable and durable.

This process helps to create flat surfaces that is horizontal vertical and at a that take the work table as a reference. It is a very useful machine and mostly used in die making industries. This motor was taken off a machine in a home shop.

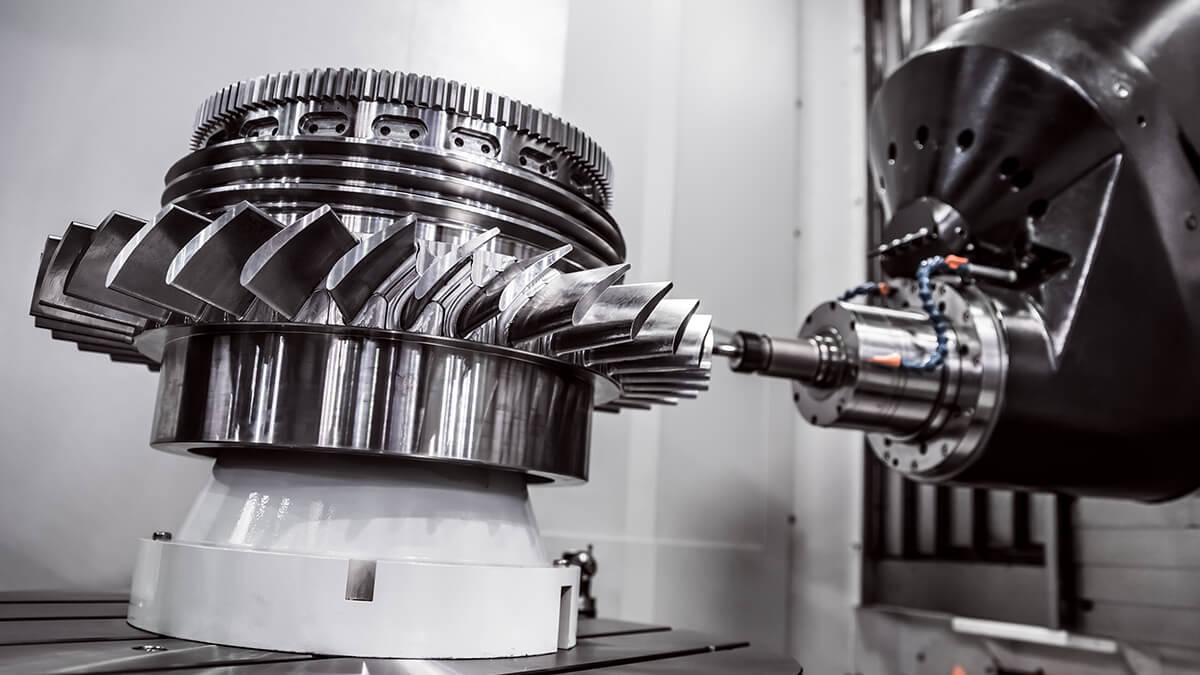

It is a milling machine that works vertically and creates a wide range of objects. The milling machines can perform almost every milling operation like gear milling thread milling angular milling etc. Jet VM-M25 1-12HP 1 PH motor for JVM 836 milling machine.

The arm and arbor supports are used to stabilize long arbors. VM-M25 1-12HP 1 PH motor VM-M20. Find used vertical milling machines and horizontal milling machines on Machinio.

It was taken off and replaced with a 3PH motor. These all movement is hydraulically controlled which is commanded by a computer. The 5-axis milling machine is composed of three linear axes as well as two rotary axes that can change depending on the selected model.

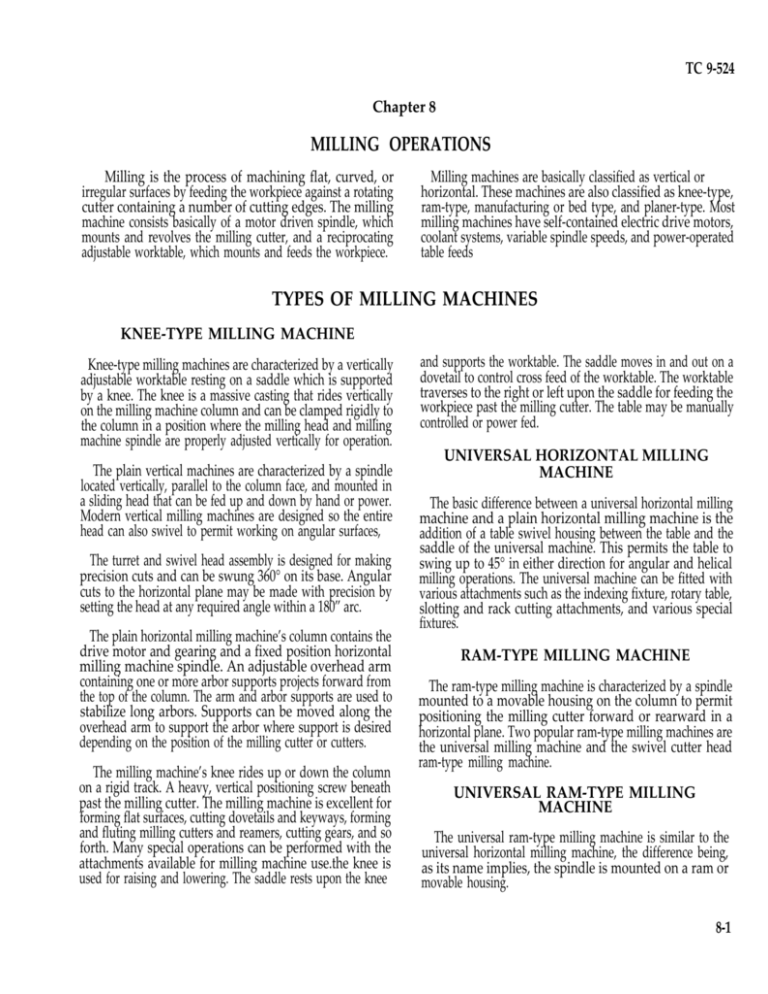

With various attachments milling machines can be used. The milling machine removes metal with a revolving cutting tool called a milling cutter. One for the cutter one for the work and the third for the longitudinal movement of the cutter.

This operation is generally used for brassbronze and ferrous materials. It has very high starting torque. This makes the flat surface at the face of the workpiece.

Bridgeport DeVlieg and TOS milling machines for sale. Applications of different DC motors are given below. It is more powerful than a turret and ideal for industries.

The table length and width Maximum longitudinal cross and vertical travel of the table number of spindle speeds and feeds Power of driving motor Floor space and net weight. It was used by the clockmakers at that time. The operation requires three driving motions in the machine.

The 5-axis milling machine. The spindle motor of the horizontal milling machine has high power and wide range of shifting speed giving full play to the tool performance and high-speed cutting. Different cutters are used for profile milling.

End milling operation. Supports can be moved along the. Face milling is done on the surface of the workpiece which is placed perpendicular to the axis of the cutter.

A milling machine removes metal by rotating a multi-toothed cutter that is fed into the moving workpiece. So it has had very little use. Included with the motor is.

Most of the milling machine classified above has self-electric driven motor coolant systems power operated table feed and variable spindle speeds. Specification of Machine Tools Lathe Milling Drilling Shaping. This operation is done performed by a face milling cutter mounted on a stub arbor.

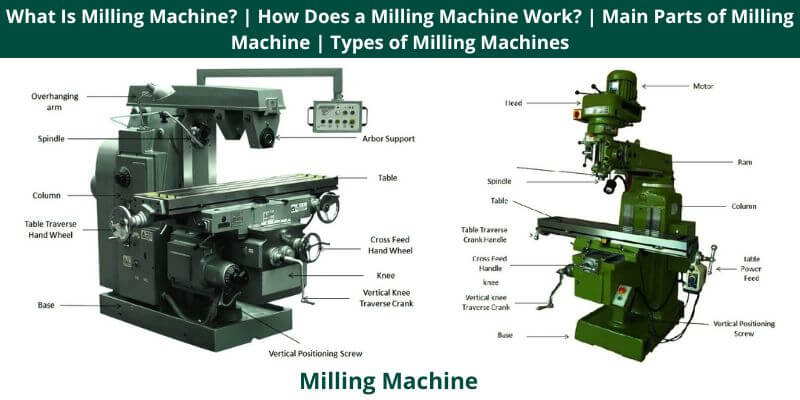

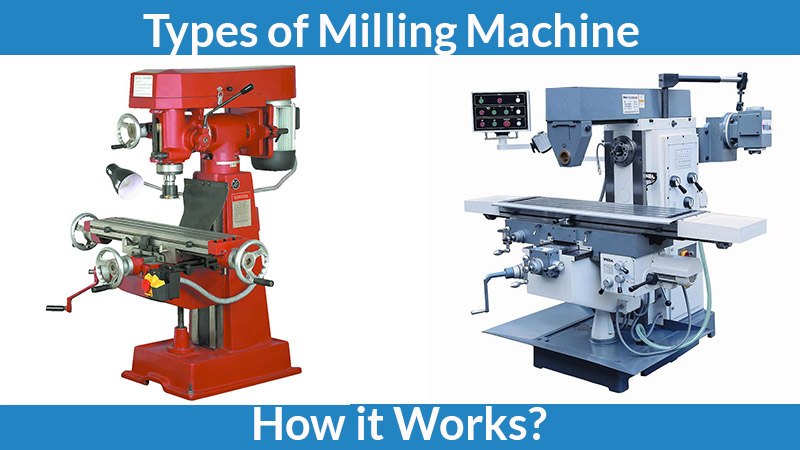

First understand What is Milling Machine. These machines are also classified as knee-type ram-type manufacturing or bed type and planer-type. In horizontal milling machine the axis of rotation of the spindle is horizontal to the table.

The milling machines are used to remove metal from the workpiece to get the desired shape with the help of a revolving cutter called known as a milling cutter. Most milling machines have self-contained electric drive motors coolant systems variable spindle speeds and power-operated table feeds TYPES OF MILLING MACHINES KNEE-TYPE. The only difference for the 4-axis milling machine is that a rotary table is added.

An end mill is one of the widely used milling. An adjustable overhead arm containing one or more arbor supports projects forward from the top of the column. Up milling or climb up milling a conventional milling machine is generally used for rough surface cutting operation.

Milling machines require constant operating speed and low starting torque. It is regularly used in the automotive and aviation industries. Thread milling operation is performed in special thread milling machines to produce accurate threads in small or large quantities.

It is an upgraded version of the bed type mill machine in which the spindle can move in all three directions and the table can rotate 360 degrees. What are the specifications of milling machine. The bed can also by fed in the x y and z axes manually.

The most popular operation done on milling machine is described below. Turret milling machines are for those who wish to work on heavy solids such as metals. Most milling machines.

In this milling operation two or more milling cutter are used together to perform different milling operations simultaneously. The motor cover that adapts mounts the motor on the pulley housing JVM836-42B. As we know that milling can perform various operations to convert the work piece into desire shape.

Milling machines are basically classified as vertical or horizontal. The 4-axis milling machine.

What Is Milling Machine How Does A Milling Machine Work Main Parts Of Milling Machine Types Of Milling Machine

Milling Machine Parts Types Operations Milling Cutter Pdf

Milling Machine Definition Parts Operation Working Principle Application Advantages Notes Pdf

Operation Of Milling Machine Engineering Learn

What Is Milling Machine Operation Parts And Types Mechanical Booster

How To Use A Milling Machine Safely Free Step By Step Guide

Vertical Turret Milling Machine Model 3 With Dro M1tr Type Table Size 1250 X 254 Banka Machine

Milling Machine Parts And Their Functions Yaletools

Milling Operations Types Of Milling Machines

What Is A Milling Machine And What Are The Parts Of A Milling Machine Market Prospects

Milling Machine Types Parts Processes Learn Technology Online

What Is Milling Machine Parts Operation Diagram Engineering Choice

What Is Milling Machine Operation Parts And Types Mechanical Booster

Milling Machine Types Working Parts Operations Cutting Parameter

Vertical Milling Machine Download Scientific Diagram

Milling Machine Parts Types Operation Unbox Factory

Comments

Post a Comment